- Home

-

About us

- News

- Solution

- Equipment

- Sanitation Vehicle

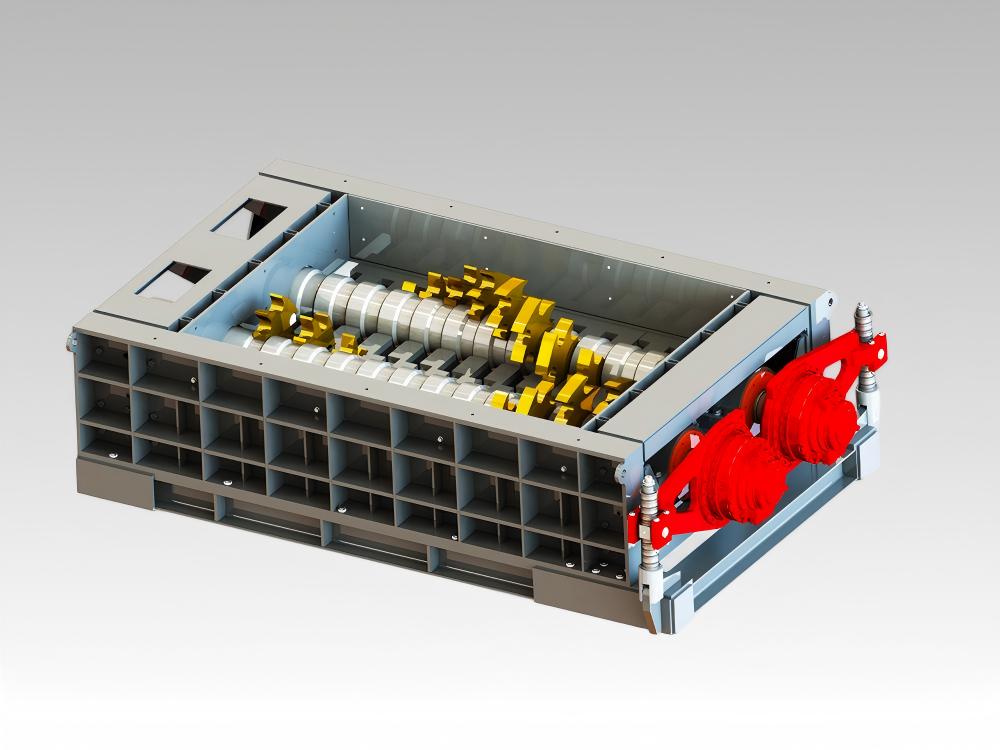

MSW pre-shredder

HCH

The MSW pre-shredder is a low-speed, high-torque, high-capacity dual-shaft crusher designed for the coarse crushing of domestic waste. Featuring a specially designed high-efficiency reversible knife shaft, it enables bidirectional crushing. As a core pretreatment equipment, it is essential for municipal solid waste sorting and waste-to-energy incineration processes.

Huanchuang Technology's pre-shredder has been successfully applied in numerous domestic and international projects, including municipal solid waste sorting and waste-to-energy incineration, earning widespread recognition from clients for its outstanding performance.

Product highlights

HIGHLIGHTS

Huanchuang Technology's municipal solid waste pre-shredder is designed with multiple advanced technologies, achieving a maximum shredding capacity of 100 tons per hour, with the crushed waste particle size ranging between 150-200mm.

Employing a heavy-duty design, it is suitable for the shredding and pre-processing of mixed waste such as household waste and construction debris. Featuring high torque, high processing capacity, and impact resistance, it can adapt to various feeding methods including grab bucket feeding, loader feeding, and chain belt feeding,

The pre-shredder’s shaft features a special design, crafted from imported special alloy steel, ensuring wear resistance, impact resistance, high strength, and the capability for overlay welding repairs, significantly extending the tool replacement cycle. The pre-shredder employs hydraulic drive, delivering stable crushing torque output, impact resistance, and reliable durability.

Performance Characteristics

1. The MSW pre-shredder adopts a modular design with a split-type housing, enabling quick disassembly, assembly, and maintenance

2. Bi-directional spindle design enables crushing in both forward and reverse directions, enhancing crushing efficiency

3. The feed hopper is designed according to project requirements to prevent material blockage and improve crushing efficiency.

4. Equipped with a rapid discharge door. When dealing with difficult-to-break materials, such as stones, concrete, metal chunks, etc., they can be quickly expelled.

5. Multi-seal technology prevents liquids and dust from entering the bearing interior, thereby protecting the bearing from corrosion. The housing is equipped with an anti-wear device, enhancing the machine's wear resistance and corrosion resistance.

6. The spindle is forged from alloy material and undergoes multiple tempering heat treatments, ensuring high strength and impact resistance. A tungsten carbide wear-resistant layer is deposited on the surface through surfacing welding to enhance wear resistance and extend the equipment's service life.

7. Special anti-tangling fixed blade design. Prevents the entanglement and jamming of strip materials and woven fabrics.

8. Based on the characteristics of different types of domestic waste, the blade arrangement is divided into four types: L, V, S, and X, to enhance crushing output and efficiency.

9. The cutting tools are made from imported wear-resistant special steel, ensuring durability and strength. After wear, the tools can be repaired by overlay welding without disassembly. Customizable and interchangeable cutting tools are available for easy inspection and maintenance.

10. Equipped with an imported European hydraulic drive system, featuring constant power control to deliver smooth maximum crushing torque.

11. Designed with multiple intelligent working modes, it can adopt corresponding modes according to different working conditions to enhance crushing efficiency.

12. The electrical control system employs internationally renowned brands such as Siemens, ABB, and Schneider, featuring automated operation, remote control, and intelligent analysis of production data. It can seamlessly integrate with the PLC or DCS control systems of project owners.

- News