- Home

-

About us

- News

- Solution

- Equipment

- Sanitation Vehicle

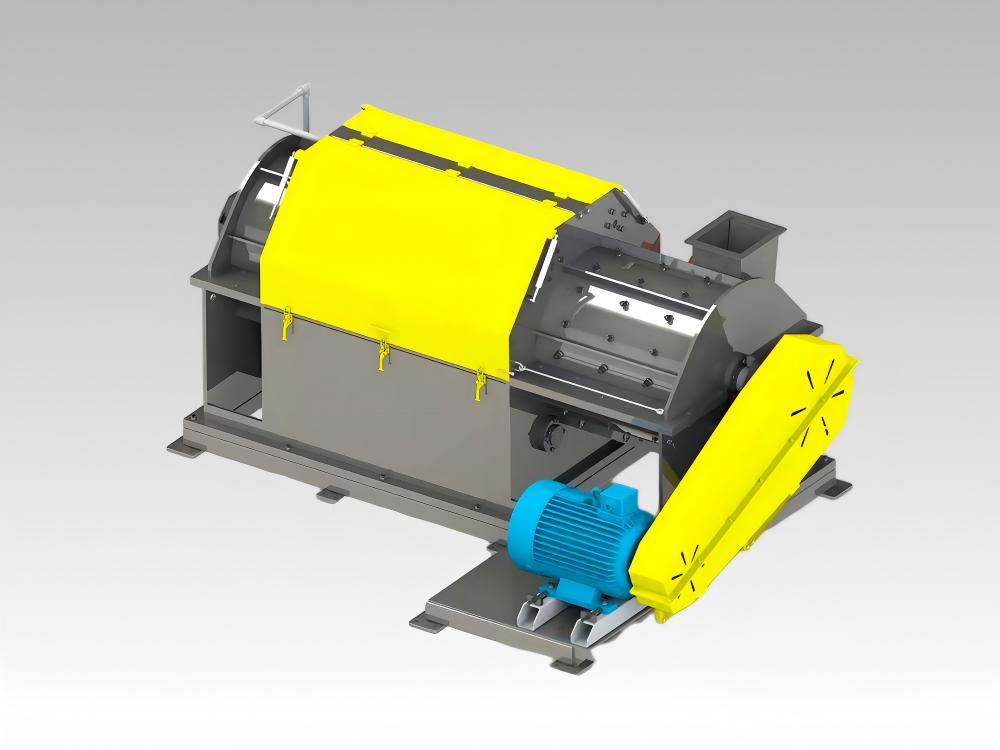

Food waste crusher

HC-FWS

The HC-FWS series food waste crusher is specifically designed for crushing and pulping organic solid waste such as kitchen waste, fruit and vegetable waste, and vegetable market waste. It adopts an innovative design technology that combines rigid crushing, flexible crushing, cleaning, multi-stage crushing process, and centrifugal dehydration to crush and pulp organic matter in kitchen waste, while separating metal, wood, plastic and other impurities, achieving the separation of organic matter slurry and inorganic impurities. The separated organic matter slurry can be used for resource utilization such as oil extraction and anaerobic biogas production.

The high-quality organic matter slurry processed by the Environmental Innovation Technology pulping machine has a solid content of less than 3% (such as metals, plastics, wood, shells, glass, stones, etc.), a slag moisture content of less than 40%, and a slag slurry content of less than 2%, ensuring that the organic matter is fully recycled and reducing the difficulty of subsequent processes, thus reducing the waste of organic matter.

Product highlights

HIGHLIGHTS

To meet the needs of different processing technologies in the market, the designed processing capacity of this series of pulp separators ranges from 5T/H-25T/H. The whole machine is designed in a fully enclosed manner, without any leakage of exhaust gas or wastewater. Each discharge point and work area is equipped with transparent and quick disassembly fiberglass windows and inspection ports for easy monitoring and sampling.

As the core equipment for the pre-treatment of kitchen waste, this pulping machine can be used in conjunction with different processes and equipment to improve the disposal efficiency of the process plan.

The kitchen waste pulping machine of Environmental Creation Technology is divided into a crushing zone, a separation zone, and a discharge zone.

The hammer in the crushing area is made of special wear-resistant steel, with a specially designed shape that forms a crushing force with the toothed lining plate. It can effectively crush organic matter, but will not completely crush flexible materials such as plastic bags/films, reducing the probability of inorganic debris and avoiding contamination of the slurry purity by impurities.

The separation zone uses flexible crushing technology, spiral arrangement, and extracts and transports materials under high-speed rotation of the main shaft. After high-speed centrifugal tapping, the organic matter slurry is separated through a sieve. After being transported, cleaned, and dehydrated, plastic film, wood, and other debris are transported to the debris discharge outlet to produce high-quality organic matter slurry.

The discharge port is equipped with a special blowing device that generates high-pressure airflow to blow out the separated plastic, wood, and other debris, achieving the separation of debris from organic matter slurry.

Performance characteristics

1. The kitchen waste pulping machine of Huanchuang Technology adopts a unique rotating screen design, supported by heavy-duty rotary bearings to reduce friction and ensure smooth operation. And it adopts frequency conversion control, with adjustable speed to adapt to different working conditions.

2. The screen mesh is made of stainless steel plate, which is impact resistant and corrosion-resistant. Equipped with drum cleaner and flushing spray device to prevent screen clogging or material hanging holes.

3. The crushing hammer is specially designed according to the material's movement trajectory, and can be used interchangeably in both directions after wear.

4. The slurry is discharged using a spiral, which can prevent clumping or blockage caused by temperature, viscosity, and prolonged shutdown.

5. The whole machine adopts frequency conversion regulation and is equipped with a fiberglass observation port on the slurry outlet for easy sampling and testing.

6. The bearing seat is equipped with a built-in water circulation cooling system and an external leak proof exhaust device to ensure stable operation of the bearing.

7. Layered slag discharge technology. The slag outlet has two outlets along the tangential direction of the circumference. Based on the air volume, pressure, density, and weight of the material, it automatically divides the material into two layers. The lightweight material is just blown away at the first outlet on the top layer. The heavy material with high density has just been scraped out by the blades along the tangential direction of the circumference at the bottom.

8. The chassis is welded with thick plates and profiles to eliminate stress and prevent deformation, while also ensuring durability. The inclined design is conducive to the fluidity of materials, preventing the viscous slurry at the feeding point and excessive accumulation, which may cause motor overload or blockage of the feeding port.

9. Box opening and closing system, electrically or hydraulically driven for easy opening and maintenance. The opening and closing device is equipped with a limit top plate and a safety switch, effectively protecting the safety of both humans and machines.

10. The belt is designed with an automatic tensioning device that can automatically adjust the tightness of the belt according to the preset tension value, protecting the cutting tools and belt from damage.

- News