- Home

-

About us

- News

- Solution

- Equipment

- Sanitation Vehicle

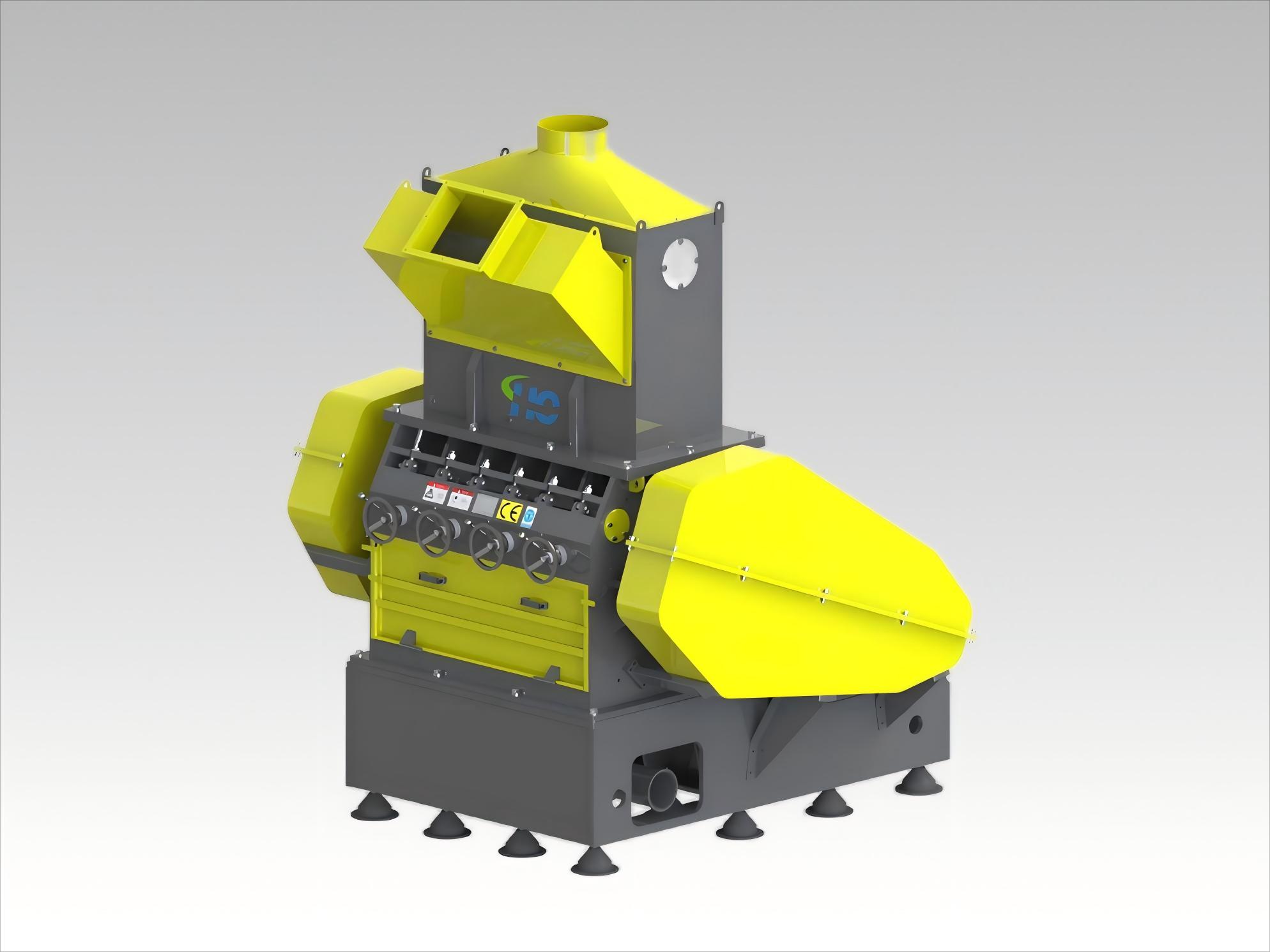

Granulator

HC-HP

The HP series granulator from Huanchuang Technology is suitable for initial crushing of large plastic sheets, pipes, films, injection molded parts and other materials, as well as secondary crushing of plastic materials, wires and cables on production lines.

This granulator is suitable for use in recycling industries such as plastic, rubber, and electronic waste. With flexible design and continuous practical innovation, it has gradually formed a series of production lines that can be selectively configured.

Product highlights

HIGHLIGHTS

The granulator determines the structure and feeding method of the cutter roller based on the different materials, characteristics, and output of the materials. It is mainly divided into structures such as universal "human" shape (R), high-efficiency shear crushing "V" shape, spiral staircase "S" shape, etc. Environmental Innovation Technology meets the needs of different fields and users through diverse design solutions. At present, the machine has been widely used in industries such as plastic, rubber, pipe, wood, food, chemical, pharmaceutical, printing, auto parts, textile, household waste recycling, and non-ferrous metal recycling.

Performance Characteristics

1.The Huanchuang Technology granulator adopts a multi-purpose crushing box design, including O-shaped box, Q-shaped box, X-shaped box, etc.

O-shaped box: mainly suitable for handling large circular and hollow materials, such as water buckets, bowling balls, oil drums, etc.

Q-type box: It is a tangent shear type granulator. Suitable for processing easily shaped and thick walled materials. Thin films, pipes, sheets, rubber, wires, etc.

X-shaped box: mainly used for high-capacity, continuous feeding and crushing. Such as online crushing of trademark film, crushing of large roll paper, plastic containers, etc.

2. Multi type blade roller design technology, including S-shaped stepped blade roller, R-type universal blade roller, V-shaped shear blade roller, L-shaped shear blade roller, etc.

S-shaped stepped knife roller: This knife roller is arranged in a narrow spiral line and has strong impact resistance. Suitable for handling wires, circuit boards, copper aluminum water tanks, PE steel wire pipes, hard rubber blocks, etc.

R-type universal knife roller: The blade is placed at the front end of the knife holder and equipped with a pressure plate, which can bear large impacts. Suitable for crushing materials that are relatively hard, thick walled, and large. Such as pipes, wood plastic panels, wires, cables, aluminum products, etc.

V-shaped scissor type blade roller: without a blade holder, the blade is directly fixed on the blade body, with a long chip cutting edge. Combined with an inclined fixed blade structure, the moving and fixed blades form a scissor type structure as a whole, which is conducive to material crushing. Low impact bearing capacity. Suitable for handling plastic film, PET bottles, fabrics, etc.

L-shaped scissor roller: The blade is equipped with a longer chip cutting edge installed at the rear, arranged in a stepped manner, which is conducive to the crushing of wide width materials and large output demands. Low impact bearing capacity. Suitable for handling rubber, tires, PET bottles, etc.

3. The belt is designed with an automatic tensioning device that can automatically adjust the tightness of the belt according to the preset tension value. If there are hard materials or blockages during the crushing process, the adjustment seat will automatically rotate in reverse to loosen the belt, effectively protecting the tool and belt from damage.

4. Equipped with a box and screen automatic opening device, using electric or hydraulic drive. It is easy to open the chassis and screen without the need for additional lifting equipment, making it convenient for maintenance and repair.

5. Customized screen design to meet the discharge control requirements of different materials and particle sizes.

7. Diversified discharge and feeding solutions that can adapt to customers' different application scenarios and overall line supporting needs. There are three ways to discharge and receive materials:

Standard type hopper, mainly used for independent operation of single machines and under the premise of low production capacity.

The air fed collection hopper transports the discharged material to the next process or centralized collection through a fan.

Transition bucket: mainly used for supporting services of the entire line, to concentrate the crushed materials into the lower conveyor mechanism through the transition bucket. Afterwards, it is usually equipped with conveyors, vibrating screens or feeders, screw conveyors, etc.

- News