- Home

-

About us

- News

- Solution

- Equipment

- Sanitation Vehicle

Channel wastewater grinder(double drum)

HCC-D

Huanchuang Channel wastewater grinder(double drum tyre) includes two sets of independent cutter shafts and two stainless steel shaftless drums in the cutting area to increase the flow rate. It is suitable for installation in channels or pump stations with medium to high flow rates, and is used to crush various types of garbage in water. The waste particle size after crushing is 8mm*12mm. The channel wastewater grinder adopts an integrated design, making installation and maintenance simple and convenient.

The wastewater grinder is installed in the rainwater/sewage pump station, pipeline network, and channel, used to crush various types of garbage in rainwater/sewage, break the garbage into fragments, prevent garbage from blocking the water pump.

Product highlights

HIGHLIGHTS

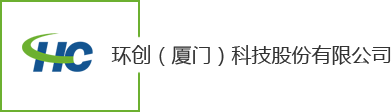

Working principle

1. Solid waste enter the channel astewater grinder with sewage;

2. Solid waste are intercepted by the drum and transported to the cutting chamber;

3. Most of the sewage and sufficiently small particles pass through the drum area;

4. Big solid wastes are grinded and passed through the grinder chamber;

5. The crushed particles flow downstream and will no longer block the pump.

Construction materials

1. Motor

Specially designed motor with multiple power options;

Submersible motor, suitable for special working conditions of submerged equipment on water surface;

2. Reducer

Planetary gear reducer with strong resistance to load and impact;

3. Blade and gasket

Imported heat treated alloy steel from the United States, with a uniformly hardened surface and a hardness of not less than 45~50HRC;

4. Axis

Imported heat treated hexagonal alloy steel from the United States;

5. Shell base

Ductile iron, wear-resistant and corrosion-resistant;

6.Drum

Stainless steel SUS304

7. Install frame

Stainless steel SUS304

Mechanical advantages

1. Easy and flexible installation

Suitable for most existing pipelines without the need for modification;

2. Tungsten carbide mechanical seal

High pressure resistance, up to 6.3kg/cm2;

No need to clean, no need to adjust the packing gland;

Hard and wear-resistant, suitable for sewage environments, reliable and durable;

3. Dual axis shear design

Stronger crushing ability, suitable for more types of solid particles than single axis crushers;

Two opposite rotating axes cause particles to be crushed between the two axes;

4. Blade selection

Design various tooth profiles according to customer needs to adapt to various special situations

5. Titanium plated blades and washers are optional

More wear-resistant than ordinary blades, and with the same usage environment, the service life is longer than ordinary blades

6. Anti blocking automatic reversal

When the garbage is too large or too much to be completely crushed at once, the machine's blade axis automatically reverses and spits out the garbage, and then crushes it again

The automatic reversal time and frequency can be freely set

7. Equipped with a quick installation system

Quickly install the system for easy installation and maintenance;

Specialized installation bracket and base, capable of wall mounted installation, channel mounted installation, etc;

8. High flow guide plate design

Increase overcurrent and reduce head loss; Simultaneously guide the garbage into the crushing chamber

9. Low base design

Ensure that the machine can still crush garbage to the maximum extent even at low flow rates

10. Use stainless steel shaftless drum (only applicable to channel single drum or double drum models)

Stainless steel material, rust resistant, suitable for sewage environment;

The drum is designed with no shaft and spiral winding, which can effectively reduce garbage entanglement or blockage;

11. Top fastening device

It can be easily tightened and repaired without the need to remove the equipment from the channel

12. Small gap between the drum and cutter

The small gap between the drum and the crusher enables higher solid capture efficiency

13.Bearing guide device

Guide solid impurities into the cutting chamber to protect the seal from damage by sand and gravel

Control Cabinet Features &Advantages

1.PLC Control Cabinet with Siemens touch panel, real time monitoring loading.

2.Remote control: MODBUS Communication standard interface .

3.Multi functions Setting: running time ,reverse time,current,start time,close time,etc.

4.Automatic Reversal Function, time and times setting of reversal.

5.Protection:Leakage,over capacity,overheating, short out and lack of phase protection functions.

6.Main parts with international well-known brand:ABB,Schneider,Siemens,etc.

Technical parameter

PARAMETERS

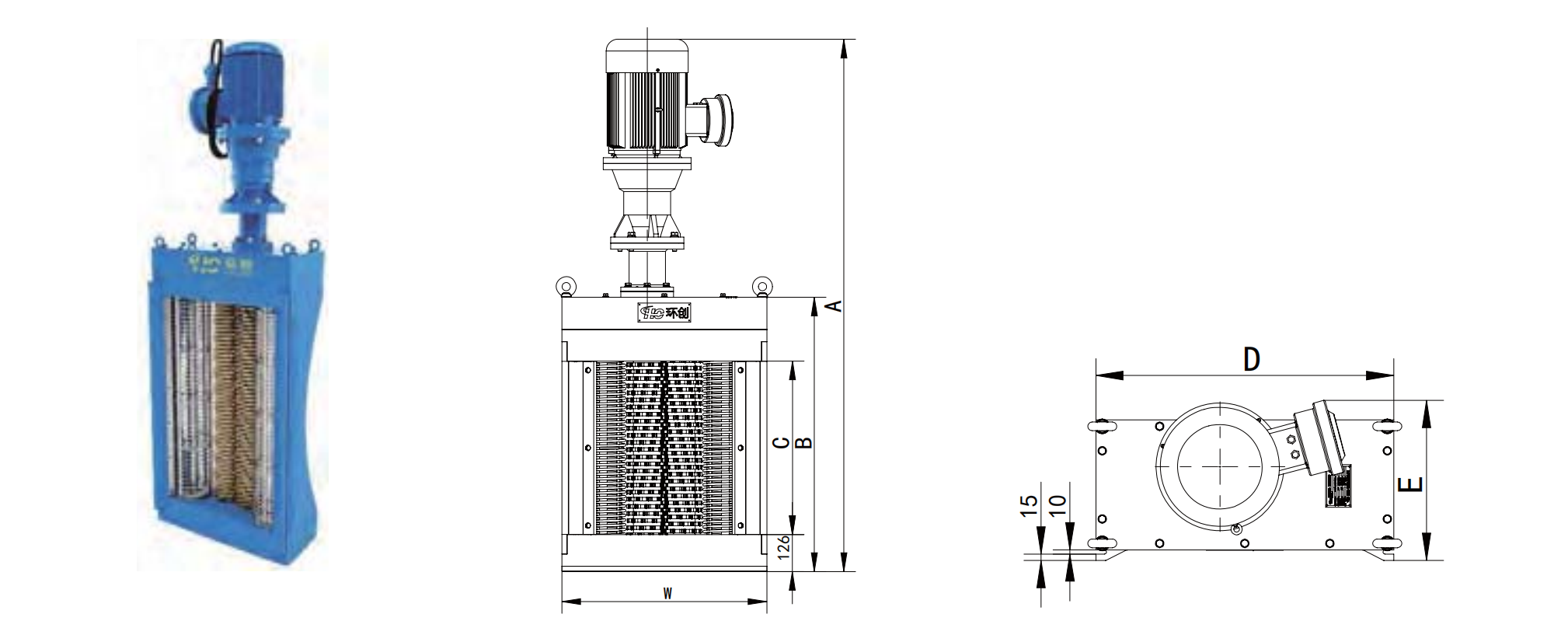

Model

Flow Rate

(m3/h)Dimensions(mm )

Min. Channel width

W(mm)Power

(kw)Weight

(kg)A

B

C

D

E

HCC-D1100

1100

1817

936

699

700

380

700

7.5

670

HCC-D1600

1600

2035

1154

810

700

380

700

7.5

740

HCC-D2000

2000

2026

1152

818

940

450

940

7.5

1174

HCC-D2200

2200

2277

1396

1052

700

380

700

7.5

815

HCC-D3000

3000

2579

1430

1086

1240

565

1240

11

1800

HCC-D4000

4000

2646

1497

1153

1240

565

1240

11

2003

HCC-D5200

5200

2906

1757

1413

1240

565

1240

11

2205

- News