- Home

-

About us

- News

- Solution

- Equipment

- Sanitation Vehicle

Garbage Compactor Truck

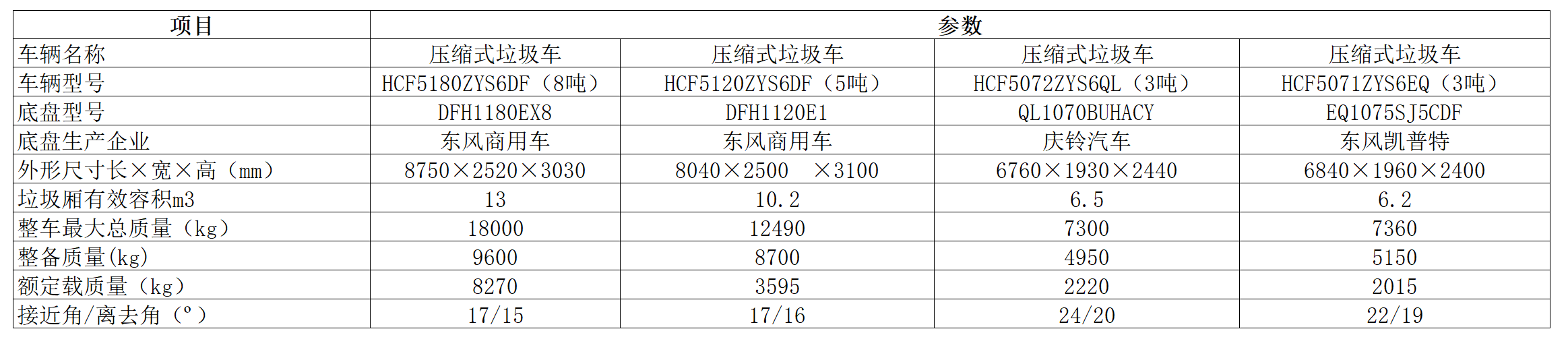

HCF5180ZYS6DF / HCF5120ZYS6DF

HCF5072ZYS6QL / HCF5071ZYS6EQThe garbage compactor truck HCF5071ZYS6EQ is the compressed garbage truck,which is developed by Huanchuang Technology and has a large loading capacity and no secondary pollution. Adopting the Kept EQ1075SJ5CDF National VI chassis, it has strong power and high vehicle configuration. Widely used in garbage collection and transportation operations for environmental sanitation and municipal services.

Product Details

Product Details

1. Adopting imported electronic control system, integrated design of electromechanical and hydraulic systems, and bidirectional compression method, the compression ratio reaches 1:4 or above.

2. The filler guide rail adopts a circular arc guide rail, which has the effect of secondary compression.

3. When the filler is lifted, the scraper can perform a secondary cleaning to ensure that there is no residual garbage during unloading.

4. The front door of the vehicle is fully sealed, and the integrated design of the filler and sewage tank completely solves the problem of secondary pollution caused by running, emitting, dripping, and leaking; Adopting a diversion type dedicated sewage collection device, the garbage and sewage squeezed out during the compression process are diverted to the sewage tank, preventing the leakage of sewage and odors.

5. The connection between the carriage and the filler adopts three barrier type sealing strips and an automatic locking hook device, which has superior sealing performance. The rear door uses pneumatic doors for easy operation.

6. The main components of the carriage are made of high-strength weather resistant steel plates, which have strong impact resistance; The sliding block of the push plate is made of nylon wear-resistant material, which reduces sliding resistance and wear of the motion pair, while also reducing the noise during operation.

7. The vehicle is equipped with 17 safety protection devices to ensure the safety of operators: contact buzzer, emergency stop device, anti roll in, abnormal overflow valve, filler lifting special oil cylinder, interlock switch, safety rod, filler lifting alarm device, etc.

8. Optional 240L, 660L, 1100L standard bucket lifting and flipping mechanism, as well as floor standing tipping mechanism.

Technical parameter

PARAMETERS

- News